It is time to wrap up the bowsprit end of things by reviewing stemhead and traveller arrangements.

A number of things tend to happen at the stemhead. Firstly, you need some sort of support or guide for the bowsprit. Secondly, except in the case of sloops like the Shrimper or Gypsy, there needs to be an attachment for a forestay.

Thirdly, provision is needed for running out anchor or mooring cables. Compared with the now “conventional” inboard rig of a Bermudan yacht, all these things are made more difficult by the inclusion of a bowsprit.

Staying Put

So you want to attach a stay to the stemhead. Ideally the connection for that stay should be as strong as the stay – usually easily achieved – and as stiff as possible to prevent needless sag on the luff of the sail hanked to it. I’m not getting racy here, but the sideways sag of a wire will be between about 40 and 200 times the vertical deflection of the end, depending on your starting conditions, and any lateral sag will be to the detriment of your windward performance. Now with a gaff rig you have to accept some reduction in windward performance for a whole variety of practical and aerodynamic reasons by comparison with Bermudan rig. That is fair enough, because there are a number of compensating advantages to the rig. But I really cannot see the point of knowingly making the situation worse, and nor did our predecessors, who knew a good deal more about the whole thing than I ever will. Consider the stemhead arrangements of working craft built in the early part of this century. You will find that the forestay is usually taken direct to the stemhead by means of a large plate mounted either on the side or the front of the stem, or via a dumb sheave through the stemhead itself so that the forestay is tensioned on the foredeck. Simple, cheap and effective. The bowsprit itself is mounted beside the stemhead. Now have a look at yachts from the same sort of period, and you will tend to notice that the bowsprit has moved over to the centreline, necessitating some sort of arched arrangement to carry the forestay. Why? Because the owners didn’t want the yachts “to look like fishing boats”. Aside from the fact that such an arrangement precludes the option of raising the bowsprit in harbour, it is also nearly impossible to build the same stiffness into such a fitting as a simple plate unless you add huge amounts of material and hence weight. Even worse from a design point of view than an arch-shaped stemhead fitting is one which encloses a squared off bowsprit and which therefore has a flat top onto which a longitudinal lug has been added on the centreline. I can at this stage either do a heap of sums, or merely state that such an arrangement is structurally horrid. Besides, having an off-centre mounted bowsprit often opens up more options for inboard retraction of the bowsprit since it is already pointing down one side deck rather than directly at the cabin front, and also frees up prime deck space on the centreline for such items as windlasses and cleats.

I don’t want to get hung up on this, but it is an example of how “yachtifying” traditional arrangements can lead to increased cost and reduced functionality. I’m encouraged that a number of recent designs – e.g. Golant Gaffer, Brock 24, Walnut 17 – have reverted to the effective stemhead arrangements developed over centuries.

Anchor Gear

Anchor operation and stowage is an area which has changed markedly over the past few decades in response to the demands of family sailing. Principal areas are the wider use of windlasses, whether manual, electric or hydraulic, improvements in the design of anchors, allowing lighter ones to be used, and the development of self-stowing systems for them. Look at most modern production boats and you will see vestigial bowsprits and/or twin roller bogeys and/or protection plates on the stem to prevent the flukes gouging the hull and/or a combination of these. In terms of functionality and freeing up deck space, the most successful efforts in my view are the solutions adopted on high speed motor cruisers, even though the snout at the stem which results is perhaps – how shall I put it? – aesthetically challenged. The point here, however, is that the presence of a bowsprit really fouls up many of the convenient and effective improvements which have been developed on “mainstream” craft. Some craft are going in the direction of fitting a stowage on the bowsprit itself, perhaps 2ft (0.6m) or so outboard of the stem. That can be made to work quite happily, but has a number of drawbacks. Firstly it precludes the use of a traveller, unless that is fitted outboard of the anchor stowage. Secondly, bowsprit retraction is no longer an option. Thirdly, is it good practice to have the loads imposed by an anchor bearing on a bowsprit which is not tensioned by its normal service loads – you are bringing a whole new set of forces into play – and finally how do you organise the safe retention of the anchor and/or cable in the outboard roller(s)?

I have to confess that I have no ready answers. We spent some time recently on a smack yacht with stowages, blocks, tackle and an anchor trying to achieve a workable solution, noting as we went how bright ideas on paper can be totally unworkable in practice! We came to the conclusion that the best bet may be to fit a stump bowsprit below the actual one for the purposes of stowing the anchor clear of the hull, but rigged such that the load of the cable can be transferred to the stemhead once the anchor is in use. Not quite an original idea, since the Dutch adopt this kind of thing on their round bowed craft, and catheads – off the centreline – have been used for centuries.

The next main area of grief is the clash between the anchor cable/mooring warp and the bobstay. Options for dealing with this include

– being able to slacken and/or hoist the bobstay out of the way, which is probably the most common solution

– retraction or raising of the bowsprit while at anchor

– having a roller each side of the stemhead, which is fine for a short period, but unlikely to induce peace of mind or be easy to operate for longer than a tide.

My sense is that in this whole area, the main improvement to import from modern practice is to use the lighter anchors now available. In itself, that might allow a re-think of the equipment needed for anchor handling. For example, it is worth considering whether you need a windlass at all. It depends of course on the size of boat, strength and skill of the crew, frequency of anchoring, and techniques used for breaking out the anchor. I would guess – but no more than that – that on a craft of less than 8m a windlass is likely to be an unnecessary complication. It may be more appropriate to incorporate a pawl into the stemhead. See Cunliffe, Hiscock or Tregoning – to name just three – for techniques involving sailing the anchor out and the use of pawls.

Another aspect which should be questioned is the need for an anchor roller. I suspect that if you are handling the chain or warp yourself, you don’t need one. I know that on smaller craft – say up to 6m – it is often hard to incorporate a sensibly sized roller into the stemhead arrangements in a fashion which is pleasing to the eye. What we have done on a number of occasions is to build in a round-down into the stemhead fairlead. It works well, and reduces the complexity, height and cost of the fitting. Beyond that, I think one is more or less stuck with traditional arrangements for anchor stowage and operation in a vessel fitted with a bowsprit.

Traveller’s Tales

I’d better move on to travellers. The point of a bowsprit traveller is to allow a jib to be set without having to go out to the end of the bowsprit. A useful side effect is that they can be used to increase the tension in a jib luff. You haul the thing nearly out, make off the halyard as best you can, and then haul out the traveller to get the final tweak.

When it comes to sizing and dimensions, a number of factors need to be borne in mind:

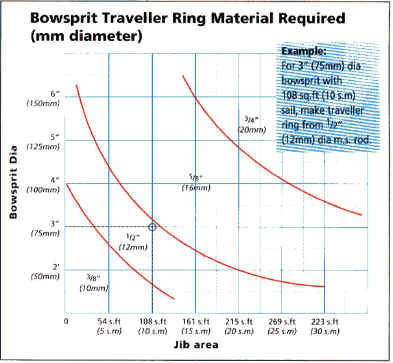

– the traveller ring takes significant loads, about the same as the jib halyard, so you need to err on the side of strength (see chart). Note how the diameter of the bowsprit drives the required material of the ring almost as much as the sail area.

– rules of thumb may not work for sizing. One I’ve heard is that the traveller ring should be 25% larger than the bowsprit, which can lead to too small a clearance on small sprits – say 50mm dia – and too large on large ones of say 300mm diameter. What we tend to do is take the largest diameter of the bowsprit and add 30mm to give the internal diameter of the traveller. Please remember that if the bowsprit goes from round to square at the inboard end, the traveller will need to circumscribe the square. I think I’ve only forgotten this once.

– sometimes the critical dimension will be driven by the requirement to pass the traveller over the cranse iron for ease of fitting and removal.

When it comes to the details of the thing, the traditional pattern – with a shackle-style outhaul loop and hook for the sail tack as shown on the left – is pretty good. If however you are planning to use furling gear on a traveller, we have found it helpful to replace the hook with a couple of plates on the traveller ring. These are then bolted through the lower eye on the furling gear, so holding the furling line lead in the right direction. This helps to prevent embarrassment on occasions. If need be, you can revert to setting a sail direct from the traveller by removing the furling gear, and bolting or pinning the tack of the sail between the two plates. The only other modification which we have found useful on bowsprit travellers is to incorporate the outhaul loop rigidly onto the main ring. This helps to prevent jamming, because tension on the outhaul loop brings the traveller into line, and reduces the bulk of the fitting

When it comes to the details of the thing, the traditional pattern – with a shackle-style outhaul loop and hook for the sail tack as shown on the left – is pretty good. If however you are planning to use furling gear on a traveller, we have found it helpful to replace the hook with a couple of plates on the traveller ring. These are then bolted through the lower eye on the furling gear, so holding the furling line lead in the right direction. This helps to prevent embarrassment on occasions. If need be, you can revert to setting a sail direct from the traveller by removing the furling gear, and bolting or pinning the tack of the sail between the two plates. The only other modification which we have found useful on bowsprit travellers is to incorporate the outhaul loop rigidly onto the main ring. This helps to prevent jamming, because tension on the outhaul loop brings the traveller into line, and reduces the bulk of the fitting

You get the best from your traveller if you can haul the thing out to the maximum extent. Ideally the outhaul sheave is mounted outboard of the cranse iron, at a slight angle from the vertical so that the outhaul line and its fall don’t foul the jibstay and bobstay lugs. But if you have a capped cranse iron, this is not likely to be an option. The usual solution here is to fit a sheave inboard of the cranse iron, which naturally means that you can’t haul the traveller out to its maximum extent. Quite often the view is expressed that such a configuration weakens the bowsprit, but since the likely failure mode is buckling rather than compressive, it shouldn’t affect things much. In both of the above cases, the fall of the traveller outhaul starts from a point underneath the bowsprit and should pass under, not through, the traveller . I have seen many instances where it is led back in such a way as to allow chafe on one or other of the stemhead fittings or be trapped by the traveller. It is unlikely to be life threatening if the outhaul parts or jams, but who needs it? Please check yours.

If for whatever reason you can’t incorporate a sheave into your bowsprit, a possible variation is to attach a block for the outhaul to the jibstay – upper – lug of the cranse iron. In this case you should lead the fall through the traveller to help reduce chafe. Additionally, the fall comes naturally to the top of the bowsprit, which is usually easier to make off. Finally, because of the loads on the traveller, some form of covering on the ring – usually leather or rope serving – is essential to protect the bowsprit.

I think that wraps it up for bowsprits, so that means I need to move to another part of the boat next time. I think I’ll take a deep breath and tackle masts, starting with a review of buckling behaviour to give the general picture before a more detailed review of the various fittings.

.jpg)